THE RISE OF GDI

How Extrude Hone can help improve efficiency of gasoline direct injection systems

The Dieselgate scandal and the resulting discussions around diesel city bans has had a profound impact on sales of diesel engine vehicles. In 2017, sales of gasoline vehicles surpassed those of diesel vehicles in Europe, traditionally a diesel stronghold, click here with countries such as France, Germany and the UK turning against diesel in a big way. One of the outcomes has been a shift in research focus in the passenger car segment towards hybridization meaning that the internal combustion engine is downsized and supplemented with and electric motor.

That said, according to ACEA (European Automobile Manufacturers Association) the decline in diesel has been “almost completely offset by an increase in the sales of petrol vehicles” and they explain that car buyers are not swapping diesel for hybrids or full EVs, rather they are switching to downsized gasoline cars instead. Many major car OEMs and their fuel systems Tier 1s are focusing more and more energy on developing their gasoline direct injection or GDI technology.

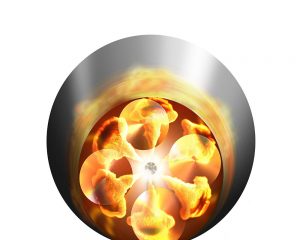

Although operating pressures are lower in GDI systems than in diesel systems (typically 350 bar as opposed to 2700 bar in diesel) partly due the gasoline’s tendency to auto-ignite, many of the requirements are similar to those of diesel direct injection and a better fuel spray and fuel atomization gives a cleaner and more efficient fuel burn leading to reduced emissions and better fuel economy.

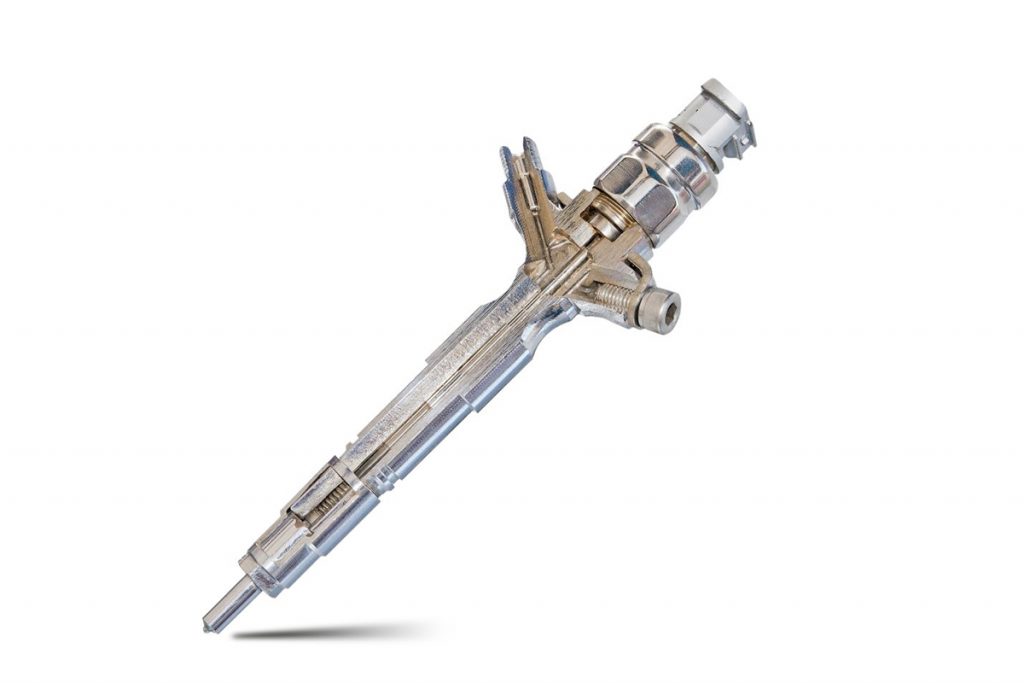

Having supported the diesel fuel systems markets for many years with its ECM and microflow technologies, it is not unnatural that OEMs and Tier 1s are turning to Extrude Hone for help to make the GDI systems more efficient and, over recent years, Extrude Hone has supported customers with the finishing of many GDI components including nozzles, needles, rails, injector cups, and pumps.

are turning to Extrude Hone for help to make the GDI systems more efficient and, over recent years, Extrude Hone has supported customers with the finishing of many GDI components including nozzles, needles, rails, injector cups, and pumps.

For nozzles and needles we use our Microflow technology to improve flow characteristics for enhanced spray pattern and fuel atomization whilst at the same time calibrating flow with tolerances as tight as ±0.5-1% with 15-20% flow rate increase (lift) or ±1-2% with lift as high as 50%.

For nozzles and needles we use our Microflow technology to improve flow characteristics for enhanced spray pattern and fuel atomization whilst at the same time calibrating flow with tolerances as tight as ±0.5-1% with 15-20% flow rate increase (lift) or ±1-2% with lift as high as 50%.

On rails and injector cups we use our ECM technology to edge radius to eliminate the risk of crack  propagation and component failure. In pump housings we use ECM to deburr to ensue 100% cleanliness of parts whilst at the same time reducing risk of cracking.

propagation and component failure. In pump housings we use ECM to deburr to ensue 100% cleanliness of parts whilst at the same time reducing risk of cracking.

For more information about our MICROFLOW and ECM technologies and how we can support you in the finishing of fuel system components, click here