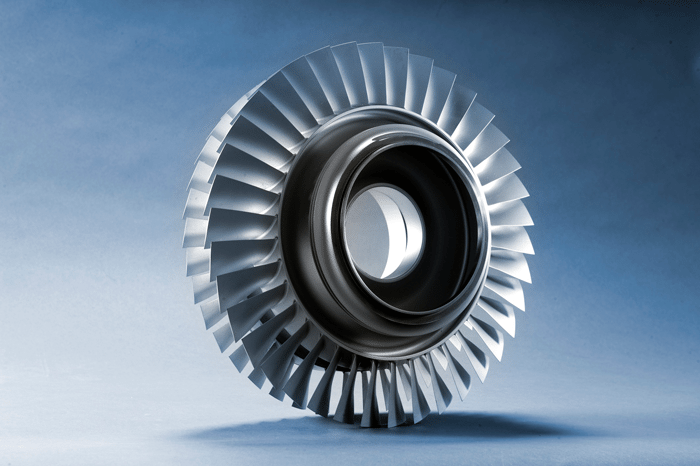

ITP Engines is adapting AFM for reliable finishing of blisks.

How ITP Engines UK and partners Brunel University and ExtrudeHone team up to get a mathematical model of the AFM process to size in the complex geometries of blisks.

Updating old abrasion process

*Courtesy of Midlands Aerospace Alliance

“In this two-year NATEP project, Leicester-based ITP Engines UK and partners Extrude Hone and Brunel University are getting to grips with the science behind a 50-year-old process used extensively to improve the surface finish on metallic parts after machining.

ITP uses abrasive flow machining (AFM) to finish integrally-bladed rotors for aero engines, often referred to as bladed disks, or blisks. These high-value blisks are manufactured from aerospace alloy forgings using expensive 5-axis milling machines on which time is always at a premium.

During AFM, a viscous abrasive paste is forced under pressure across the surfaces of parts to smooth out surface irregularities such as machining marks.

Despite being deceptively simple in concept, the process has always been largely empirical because the underlying physics and chemistry are not fully understood.

As airfoil shapes become more sophisticated, the inability to accurately predict and control the AFM process means that it is becoming increasingly difficult to preserve key features. Caution dictates that some parts need to be subjected to interim measurement on CMM machines, thereby significantly increasing the manufacturing time.

During this project, Brunel University has been constructing a mathematical model of the AFM process and validating it through a series of tests on material coupons and blisk segments carried out by Extrude Hone and ITP.

Although this project still has a little way to go, the results to date are extremely encouraging.

ITP hopes it will be possible to fully integrate AFM into the manufacturing cycle as a controlled process, and that it may even be possible to reduce milling time, safe in the knowledge that reliable finishing to size can be achieved using AFM.”